Proc. of Second World Avocado Congress 1992 pp. 467-472

Response of 'Hass' Avocado to Postharvest Storage in Controlled Atmosphere Conditions

Dana F. Faubion, F. Gordon Mitchell, and Gene Mayer

Department of Pomology, University of California, Davis, CA 95616, USA

Mary Lu Arpaia

Department of Botany and Plant Sciences, University of California, Riverside, CA 92521, USA

Abstract. The current storage temperature recommendation for avocado fruit Persea

americana Mill. cv. Hass of 5 to 7C in California gives a maximum

storage time of two to four weeks due to internal browning, caused by chilling

injury (Cl), and softening. The postharvest response of mature avocado fruit to

various storage conditions was studied to determine the' potential for

extending their postharvest life. Fruit stored in air at 5C softened and

developed severe Cl after nine weeks. Controlled atmosphere (CA) storage

delayed softening and Cl, and retained good quality after nine weeks.

Continuous ethylene exposure (1 or 10 ppm) in CA greatly increased softening

and Cl. Carbon dioxide shock treatments (ranging from 10-30% for 3 days) were

not effective in maintaining fruit quality.

Avocado fruit (Persea americana Mill. cv. Hass) can be held successfully after harvest in cold storage for approximately 2 to 4 weeks. Optimum storage temperatures for avocado vary from 4.4C to 12.8C (Lutz and Hardenburg, 1968), depending on the cultivar. Storage time is limited by chilling injury and flesh softening. Chilling injury (Cl) of avocado occurs at temperatures required to arrest ripening. Ripening occurs rapidly at non-CI temperatures and results in soft fruit that are difficult to commercially handle (Eaks, 1976; and Arpaia et al., 1987).

Experiments evaluating modified atmospheres for avocado were undertaken in the 1920's (Overholser, 1928, 1929). The effect of modification of the environment on avocado fruit respiration has been shown (Biale, 1946; and Young et al., 1962). Decreased oxygen and elevated carbon dioxide decreased the respiration rate and extended the time to reach the climacteric. Several investigators have shown that reduced oxygen and increased carbon dioxide prolonged storage but increased susceptibility to decay (Eksteen and Truter, 1985). The individual effects of low oxygen and high carbon dioxide on avocado fruit indicate a greater than additive effect of combined low oxygen and high carbon dioxide (Spalding and Reeder, 1975). High levels of ethylene in controlled atmospheres (CA) have been shown to have a negative impact on fruit quality (Hatton and Reeder, 1972). Beneficial effects of short term exposure to high carbon dioxide shock treatment followed by storage in air have been reported (Colin, 1984; Marcellin and Chaves, 1983; Truter and Eksteen, 1987). This treatment was reported to be a simpler means of extending the postharvest life of avocado.

The use of CA for avocado has been shown to

be effective (Reeder and Hatton, 1971; Spalding and Reeder, 1975; and Eksteen

and Truter, 1985), but specific requirements must be determined for each

cultivar and growing region. Optimum levels of oxygen and carbon dioxide, the

effect of fruit maturity, and the impact of low levels of ethylene exposure

during storage need to be determined. This study was initiated to evaluate the

potential for CA storage on California grown 'Hass' avocado.

|

Table

1. Characterization of

physiological development stages of the 'Hass' avocado fruit harvested from

Santa Paula, California.z |

|||

|

Harvest Date |

Flesh Firmnessy (kfg) |

Dry wt. (%) |

Days to peak C2H4 productionx |

|

2-09-90 Early |

77.2 ± 0.7w |

31.5 ± 0.9 |

13.4 ± 1.3 |

|

4-27-90 Middle |

79.0 ± 1.1 |

34.5 ± 0.8 |

9.4 ± 0.7 |

|

7-02-90 Late |

73.7 ± 0.9 |

34.7 ± 0.9 |

10.3 ± 0.7 |

|

z Range of fruit weight: 280-360 g. y Tip size of pressure gauge, 6.2 mm. x Fruit held at 20C. w ± Standard error of the mean. |

|||

Materials and Methods

Fruit were harvested at three times during the 1989-1990 season (February 9, April 27 and July 2) from a commercial 'Hass' grove near Santa Paula, California (Table 1). The timing of the individual harvests corresponded to early-, middle- and late-season commercial harvests. The fruit came from the same group of trees throughout the season. Each harvest was size picked for uniformity. The fruit were transported to U.C. Davis to be sorted for defects and cooled to 5C. All CA-treated fruit were cooled and placed in the proper environment within 24 hours after harvest. Control fruit were stored at the same temperature but in an ambient air atmosphere.

Each treatment was conducted in a separate 0.30 m galvanized steel container held at 5C. Gases were mixed and flowed through the tanks at 500-600 mL/min. Oxygen and carbon dioxide levels were monitored at inlet and outlet ports and were held within ±0.2% of the set point. Ethylene, unless added to the treatments, was <20 ppb. Fruit receiving carbon dioxide shock treatments were exposed for three days to high carbon dioxide in a flow-through system, then stored in air.

Evaluations were done initially and after 3, 6, and 9 weeks of storage. Firmness of the mesocarp was monitored using a U.C. firmness tester with a 6.2 mm tip (Claypool and Fridley, 1966). Firmness measurements were taken for each treatment immediately upon removal from storage (10 fruit) and again after 5 days of ripening at 20C and 10 to 50 ppm ethylene. Twenty fruit per treatment were evaluated after ripening for firmness and Cl symptoms (determined by flesh and vascular discoloration). Distally separated halves of the ripe fruit were evaluated visually on a 0 to 5 scale for flesh discoloration, 0 being no discoloration; and on a scale of 1 to 4 for vascular discoloration, 1 being no visible discoloration. If flesh or vascular discoloration were 3 or above, that fruit was classed as having moderate to severe discoloration. Incidence of decay after ripening was monitored by visual evaluation of the mesocarp.

Results

Firmness. Evaluations of fruit quality after nine weeks revealed that low oxygen/high carbon dioxide treatments significantly reduced softening during storage (Table 2). Fruit from all harvests held in air softened extensively after nine weeks whereas fruit stored in CA remained significantly firmer. Fruit treated with 2% oxygen and either 2.5, 5.0, 7.5 or 10.0% carbon dioxide did not show consistent differences in firmness and in all cases were firmer after nine weeks than when harvested. Treatments of 1 or 4% oxygen and 2.5% carbon dioxide were also firmer after nine weeks than when harvested for the middle harvest.

Both 1 and 10 ppm ethylene when introduced continuously in a 2% oxygen + 2.5% carbon dioxide atmosphere resulted in decreased firmness after nine weeks. No differences were observed after 3 weeks of storage.

The differences in flesh firmness of ethylene-treated CA fruit as compared to the CA control were not significantly different until 9 weeks for the 1 ppm treatment and 6 weeks for the 10 ppm treatment.

Carbon dioxide shock treatments delayed softening more effectively at lower concentrations then at higher concentrations. After nine weeks all fruit were unacceptably soft for both the early and late season fruit.

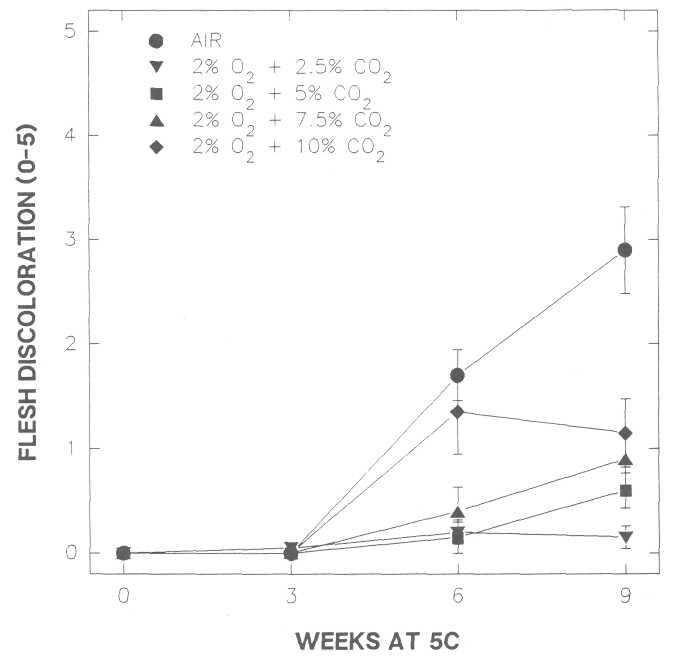

Flesh and vascular discoloration. Chilling injury, as manifested by flesh and vascular

discoloration, was significantly reduced by all the low oxygen/elevated carbon

dioxide treatments (Figure 1). Fruit from the second harvest stored in air or

2% oxygen + 2.5% carbon dioxide for 9 weeks had flesh discoloration scores of

2.9 and 0.15, respectively. Discoloration of fruit held under low oxygen and 5

to 10% carbon dioxide was significantly greater than for 2.5% carbon dioxide

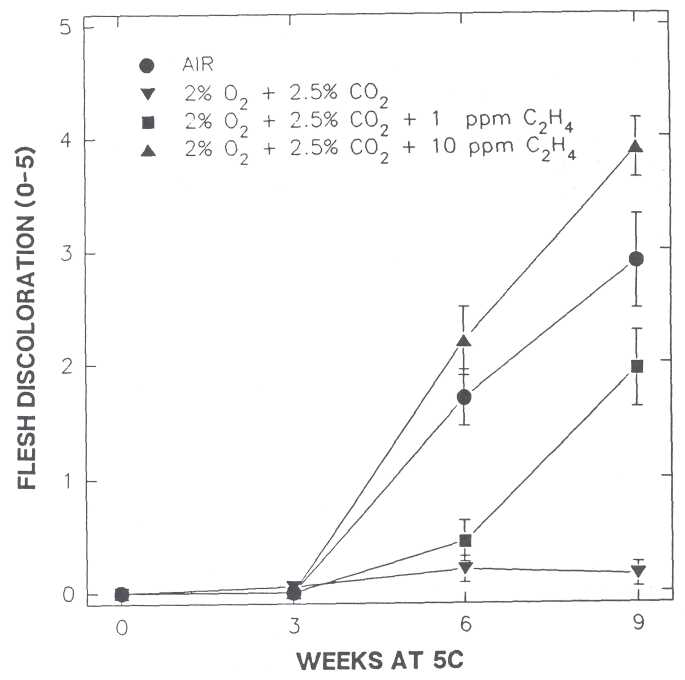

fruit after 9 weeks. Continuous exposure to ethylene during CA storage had a

dramatic effect on chilling injury (Figure 2). Both 1 and 10 ppm ethylene

significantly increased both vascular and flesh discoloration over fruit stored

in CA without ethylene. Fruit stored in 10 ppm ethylene plus CA were in poor

condition after nine weeks and were comparable to fruit held in air.

|

Table

2. Effect of nine weeks storage in

various storage atmospheres at 5C on flesh firmness of 'Hass' avocado.z |

|||||

|

Treatment |

Firmness (kgf)y |

||||

|

|

|

|

Harvest |

||

|

O2 (%) |

CO2 (%) |

C2H4 (ppm) |

Early |

Middle |

Late |

|

Air |

|

|

9.2dx |

41. 4 c |

26.0 cd |

|

2 |

1.5 |

|

— |

85. 4 a |

79. 4 a |

|

2 |

2.5 |

|

83.4 a |

81.8 ab |

77.4 a |

|

2 |

5.0 |

|

85.6 a |

83.2 ab |

78.1 a |

|

2 |

7.5 |

|

83.4 a |

85. 2 a |

76.8 a |

|

2 |

10.0 |

|

81.2 a |

83.6 ab |

77.9 a |

|

2 |

2.5 |

1.0 |

— |

77.0 b |

— |

|

2 |

2.5 |

10.0 |

— |

41. 4 c |

— |

|

1 |

2.5 |

— |

85.1 a |

74.4 a |

|

|

4 |

2.5 |

— |

83.6 ab |

— |

|

|

shock |

10.0w |

25.3 b |

— |

— |

|

|

shock |

15.0 |

22.7 b |

— |

31.2 c |

|

|

shock |

20.0 |

14.1 cd |

— |

— |

|

|

shock |

25.0 |

18.7 bc |

— |

20.5 d |

|

|

shock |

30.0 |

11.0d |

— |

— |

|

|

z Firmness at harvest: early 77.2, middle 79.0, late 73.7 kgf. y Tip size of pressure gauge, 6.2 mm. x Mean separation in columns by Duncan's multiple range test, (P<0.05). Unless otherwise noted, ethylene concentrations were maintained at below 0.020 ppm. w Shock treatments were for 3 days followed by storage in air. |

|||||

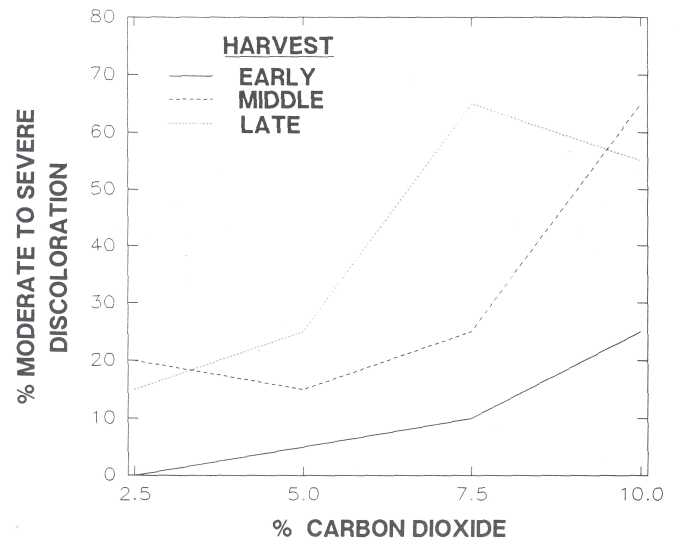

Maturity influenced the severity of the chilling injury in CA (Figure 3). Fruit from the earliest harvest showed the least discoloration in 2% oxygen and a range of elevated carbon dioxide levels. The carbon dioxide levels of 2.5 and 5% appear to be the most effective in reducing moderate to severe discoloration.

Stem end decay infections were noticeable in treatments that did not prevent loss of quality. Air stored, shock, and ethylene (10 ppm only) treated fruit had high rates of decay after nine weeks.

Discussion

The 'Hass' avocado appears to respond well to CA treatments and stored for at least nine weeks without softening or severe chilling injury. High ethylene levels (10 ppm) decrease the quality of fruit in CA as reported by Hatton and Reeder (1972). The effect of low levels of ethylene (1 ppm) may also be important. More research is needed to define the importance of low levels of ethylene and its interaction with carbon dioxide (a competitive inhibitor of ethylene action).

Carbon dioxide shock treatments were not

effective in delaying softening or Cl development in the 'Hass' avocado. Shock

treatments have been shown to be effective on 'Fuerte' (Truter and Eksteen,

1987).

The positive results reported from South Africa were obtained by initially establishing high levels of carbon dioxide (20-30%) and then sealing the containers for three days. At the end of three days, carbon dioxide had accumulated to above 35% and oxygen had decreased to below 2% (B. Truter, personal communication). Shock treatments in this test were done in a constant atmosphere, flow-through system, and this may explain the difference in results.

Optimum levels of carbon dioxide in low oxygen need to be defined, these data indicate that carbon dioxide levels above 5% may have a deleterious effect on 'Hass' avocado fruit quality.

Project

funded in part by a grant-in-aid from the California Avocado Commission.

Literature Cited

Arpaia, M.L., F.G. Mitchell, P.M. Katz, and G. Mayer. 1987. Susceptibility of avocado fruit to mechanical damage as influenced by variety, maturity and stage of ripeness. S. A. Avocado Growers' Assn. Yrbk. 8:78-80.

Biale, J.B. 1946. Effect of oxygen concentration on respiration of the 'Fuerte' avocado fruit. Amer. J. Bot. 33:363-373.

Claypool, L.L. and R. B. Fridley. 1966. Precision with a pressure tester. Western Fruit Grower 20:18-19.

Collin, M.N. 1984. Avocado storage with CO2 pulses. Fruits 39:561-566. (abstr.).

Eaks, I.L. 1976. Ripening, chilling injury, and respiratory response of 'Hass' and 'Fuerte' avocado fruits at 20C following chilling. J. Amer. Soc. Hort. Sci. 101:538-540.

Eksteen, G.J. and A.B. Truter. 1985, Effects of controlled and modified atmosphere storage on quality of eating ripe avocados. S. A. Avocado Growers' Assn. Yrbk. 8:78-80.

Hatton, T.T. and W.F. Reeder. 1972. Quality of 'Lula' avocados stored in controlled atmospheres with or without ethylene. J. Amer. Soc. Hort. Sci. 97:339-341.

Lutz, J.M. and R.E. Hardenburg. 1968. The commercial storage of fruits, vegetables, and florist and nursery stocks. U.S. Dept. Agr. Handbook 66.

Marcellin, P. and A. Chaves. 1983. Effect of intermittent high CO2 treatment on storage life of avocado fruit in relation to respiration and ethylene production. Acta Hort. 138:155-163.

Overholser, E.L. 1928. Some limitations of gas storage of fruits. Ice and Refrig. 76:551-552.

Overholser, E.L. 1929. Cold storage, ripening, and respiration studies of the 'Fuerte' avocado. Proc. Amer. Soc. Hort. Sci. 25:317-375.

Reeder, W.F. and T.T. Hatton. 1971. Storage of "Lula1 avocados in controlled atmosphere 1970 test. Proc. Fla. State Hort. Soc. 83:403-405.

Spalding, D. H. and W. F. Reeder. 1975. Low-oxygen high-carbon dioxide controlled atmosphere storage for control of anthracnose and chilling injury of avocados. Phytopathology 65:458-460.

Truter, A. B. and G. J. Eksteen. 1987. Controlled and modified atmospheres to extend storage life of avocados. S. A. Avocado Growers' Assn. Yrbk. 10:151-153.

Young, R.E., R.J. Romani, and J.B. Biale. 1962. CO2 effects on fruit respiration. II. Response of avocados, bananas, and lemons. Plant Physiol. 37:416-422.

Fig. 1. The effect of various controlled atmospheres on flesh discoloration of 'Hass' avocado after 0 to 9 weeks storage at 5C plus ripening at 20C. Fruit are from the middle harvest. Vertical bars are ± SE.

Fig. 2.

The effect of ethylene in controlled atmosphere storage on flesh discoloration

of 'Hass' avocado after 0 to 9 weeks storage at 5C plus ripening in air at 20C.

Fruit are from the middle harvest. Vertical bars are ± SE.

Fig. 3. Effect of harvest date on internal quality of 'Hass' avocado after nine weeks of storage at 5C in 2% O2 and various levels of CO2 plus ripening at 20C. Percent moderate to severe discoloration is based on fruit with a 3-4 or 3-5 rating of vascular or flesh discoloration, respectively.