Proc. of

Temperature Management - The Basis for Successful Export of South African 'Fuerte' Avocados

J.J. Bezuidenhout,

L.L. Vorster, and J.C. Toerien

Westfalia Estate,

Abstract. By using a climacteric model in which the period from picking to the climacteric peak is expressed as a function of temperature and fruit maturity (moisture content), a temperature regime has been developed for the storage of 'Fuerte' avocados during export to the European markets. Temperatures are adapted throughout the season. These temperatures range from 3.5C to 7.5C. Declining temperature regimes during shipment tend to give the best results. By applying these principles, temperatures can be selected to accommodate early season fruit which is more sensitive to low temperatures than late season fruit. Optimum storage temperatures should be varied with both fruit maturity and climacteric stage. This concept was applied during commercial export by sea during the 1989 and 1990 picking seasons. Strict maintenance of the cold chain and the time/temperature relationship was found to be very important in the successful implementation of the system.

In contrast with previous seasons, application of the system resulted in improved quality with regard to fruit firmness and reduction of external cold damage. Under commercial conditions, when deviations occurred from the recommended temperature, a significant correlation was found between the extent of the deviation and the incidence of either external cold damage or of soft fruit. When packing and transport procedures reduced the total export period from 28 to 22 days, fewer temperature-related quality problems were experienced.

The South African avocado industry is largely dependent on the European markets and relies on sea export for a large part of its sales. Long distances must be covered in this process. Consistent high quality is of vital importance. Soft fruit and cold damage are potential threats to the avocado industry from a quality point of view. Low storage temperature is the major commercial method used to prolong the shelf life of South African export avocados. Successful cold storage is dependent on knowledge and understanding of the physiology of the fruit, the physical principles and mechanism of cold storage and effective post-harvest management. The time temperature relationship is the most important determining factor of fruit quality. In contrast with previous seasons, application of a system of temperature management during the 1989 and 1990 harvesting seasons resulted in improved quality with regard to fruit firmness and reduction of external cold damage.

Results

The objective is to deliver avocados to

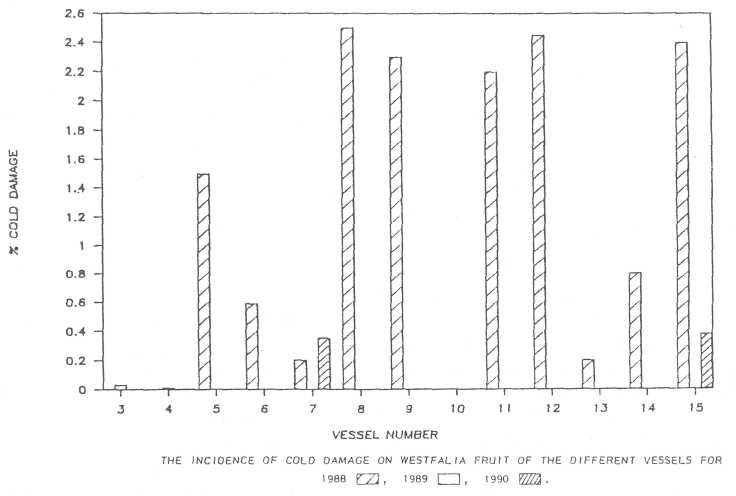

Cold damage. Figure 1 shows the extent of cold damage of Westfalia fruit during the 1988, 1989 and 1990 seasons. During 1988, fruit damage on two vessels carrying 'Fuerte' exceeded 2.5% (Vessel 8 and 12), three vessels 2.0% (Vessel 9, 11 and 15) and one vessel 1.5% (Vessel 5) - a total of six vessels where 'Fuerte' exceeded the commercially accepted standards. During 1989, external cold damage was not a commercially important problem. During 1990, only vessels 7 (0.34%) and vessel 15 (0.4%) showed signs of cold disease.

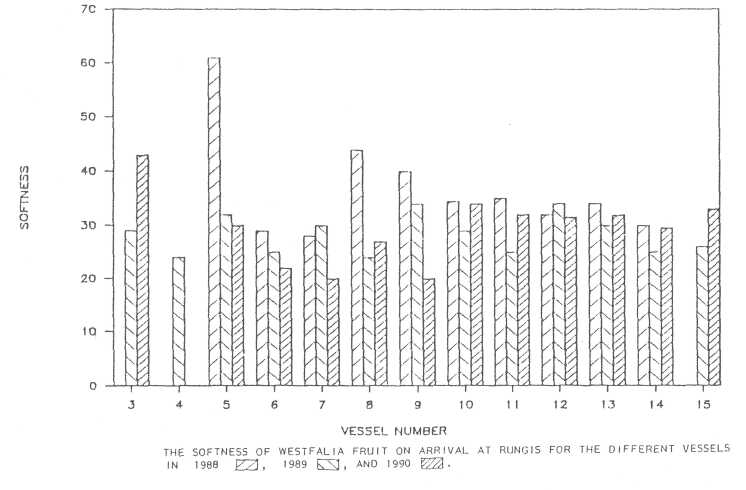

Firmness. Figure 2 shows the firmness of Westfalia fruit during the 1988, 1989, and 1990 seasons. During the 1988 season, fruit on vessels 5, 8 and 9 exceeded the commercial standards of 35 on the firmometer whereas the firmness of fruit monitored during the 1989 season were all below the accepted standards. During the 1990 season fruit from Westfalia only once exceeded the minimum acceptable standard of 35 units; and this was on the first boat (Vessel 3).

These results illustrate that the principle of temperature management is to the advantage of the South African avocado industry. Temperature management is the integration of various principles which include the following:

(i) A specific temperature regime dependent on the maturity and sensitivity of the fruit at a specific maturity stage;

(ii) Technical feedback from the overseas markets;

(iii) Time temperature interaction;

(iv) The physical principles and mechanism of cooling and cold storage;

(v)

Moisture loss; and

(vi) Selective picking.

Storage temperatures. The ideal is to export firm fruit with no external cold damage and no physiological or pathological disorders. A fine balance between firm fruit and external cold damage exists. Too high transport temperatures will result insoft fruit on arrival, while too low temperatures will result in fruit with external cold damage.

Considerable differences in sensitivity to low temperatures have been observed during different stages throughout the avocado season (Vorster, Toerien & Bezuidenhout, 1987). 'Fuerte' avocados show a definite decrease in external cold damage towards the end of the harvesting season when stored at 5.5C for 28 days.

Early season 'Fuerte' (moisture content of 77.5%) is very sensitive to a storage temperature of 5.5C over a period of four weeks and storage at this temperature can result in cold damage. Later in the season a four-week storage at 5.5C can result in soft fruit, therefore adaptation of temperatures throughout the season is necessary.

Optimum temperature and storage periods vary with the stage of fruit development (Bezuidenhout, 1983). Kosiyachinda and Young (1976) found that the chilling sensitivity of 'Fuerte' and 'Hass' avocados was highest during the climacteric rise and peak. The least sensitive stage is the post climacteric stage.

Bezuidenhout (1983) formulated a climacteric model and Toerien (1986) proposed the concept of a declining temperature regime. The model formulated by Bezuidenhout (1983) fitted well into the concept proposed by Toerien (1986).

Climacteric model. The time to the climacteric is a function of temperature and fruit maturity and the correlation with the time to the climacteric was formulated as follows:

Tc = C1 - OL C2/Te - C3/T

where

Tc = time to the climacteric in days

T = temperature in C

OL = % oil content

e = exponential constant (2.7183)

C1 = 150

C2 = 1.3

C3 = 1.625

Historical data shows that the average time for Westfalia Estate avocados to arrive overseas is 24 days.

The temperature regime which is selected (a moderate temperature during the early stages of storage and a lower temperature during the later stages) is designed so that the fruit will reach the climacteric peak after approximately 24 days. This principle was evaluated on an experimental basis and storage temperatures were consequently proposed to the South African avocado industry (Vorster et al., 1990). The proposed temperature regime should be seen as a flexible tool in the concept of temperature management.

Recommended temperatures are air temperatures and it can be assumed that fruit pulp temperatures in a commercial system will be 1-2C higher than air temperatures (Boelema, 1987).

Using the above principles 'Fuerte' avocados with a firmness of less than 35 (as measured on the firmometer) and with the minimum amount of cold damage, can be expected if the storage period does not exceed 28 days. Strict maintenance of the transport chain is very important. Under commercial conditions, when deviations occurred from the recommended temperature, a significant correlation was found between the incidence of soft fruit and/or cold damage and the extent of the deviation.

Feedback from overseas markets. Temperature management involves the implementation of a flexible system. Fruit can change from season to season. Therefore adaptations should be made whenever necessary. Due to this reason well defined and detailed feedback of firmness, cold damage and storage temperature is essential. Although temperature information obtained from in-transit Ryan recorders may occasionally be defective, this information is still of vital importance. Should fruit arrive overseas soft or with cold damage, a record of the time/temperature regime is essential to reach a sensible conclusion.

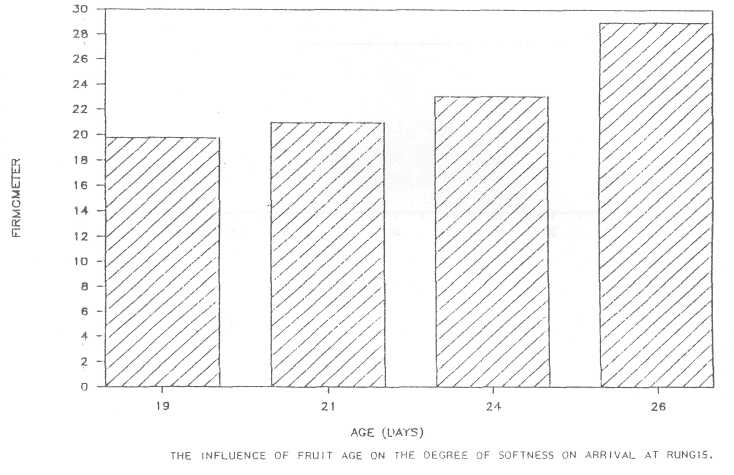

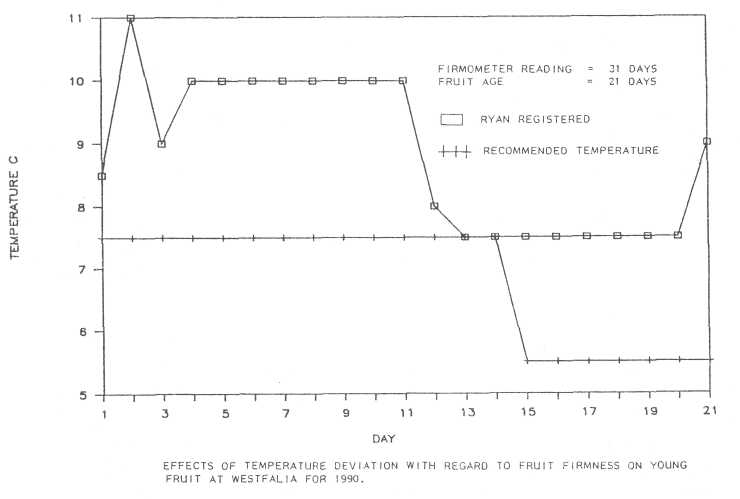

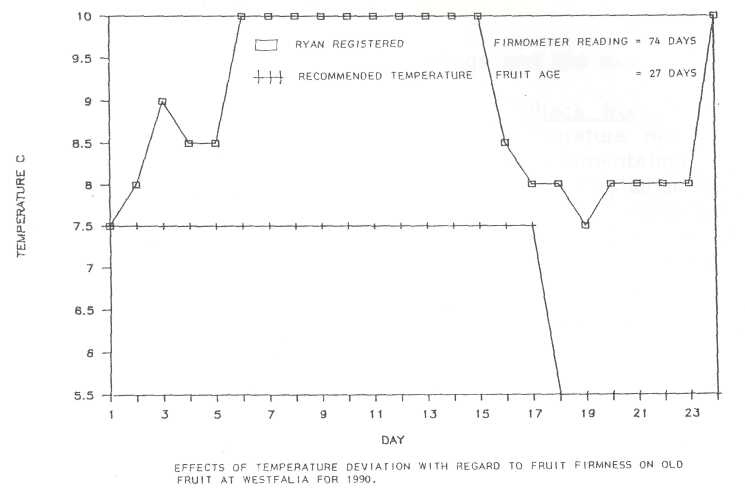

Time and temperature interaction. The time and temperature relationship cannot be overemphasized in the effort to maintain high fruit quality during shipping to overseas markets. When packing and transport procedures are reduced so that the total export period is reduced from 26 to 19 days, fewer temperature-related quality problems were experienced. This also resulted in firmer fruit (Fig. 3). When deviations from the recommended temperature regimes occur, young fruit are less prone to softness than older fruit (Figs. 4 and 5). The avocado industry must accept that there is a time constraint and thus should minimize the period of postharvest handling.

Cooling. The physical mechanism of cold storage is an important factor in temperature management and the following principles are vital to its success:

(i) Well ventilated cartons,

(ii) Configuration of cartons in pallets so as to promote optimal air flow,

(iii) Effective utilization of air in the cold room,

(iv) Uniform cooling throughout the pallet, and

(v) A controlled air flow pattern.

The above factors will bring about maximum contact between air and the product and will result in more homogeneous cooling.

Water loss. Water loss is one of the most important factors leading to fruit deterioration. Increased moisture loss resulting in stress during storage, enhances polyphenol oxidase (PPO) activity and visual symptoms of physiological disorders. (Bower and Cutting, 1987). The design of cooling systems in a packhouse plays a major role in water loss of fruit and the final fruit quality. A high humidity cold room will retard the rate of moisture loss.

Conclusions

Better quality in exported fruit has been achieved through the implementation of temperature management by the South African avocado industry. Time/temperature management includes the integration of various principles. This begins in the orchards and ends on the overseas markets.

Literature Cited

Bezuidenhout. J. J. 1983. Die voorkoms van mesokarpverkleurings by 'Fuerte' avocado's op die Rungismark gedurende 1982. S. A. Avocado Growers'. Assn. Yrbk. 6:24-27.

Boelema, T. 1987. Long distance transport of avocados. S. A. Avocado Growers'. Assn. Yrbk. 10:153-156.

Bower, J. P. and J.G. Cutting. 1987. Some factors affecting postharvest quality in avocado fruit. S. A. Avocado Growers'. Assn. Yrbk. 10:143-146.

Kosiyachinda, S. L. D., R.E. Young. 1976. Chilling sensitivity of avocado fruit at different stages of the respiratory climacteric. J. of Amer. Soc. Hort. Sci. 101:665-669.

Swarts, D. H. 1981. Firmometer ondersoek by avokado's. S. A. Growers'. Assn. Yrbk. 4:42-46

Toerien, J.C. 1986. Temperature control of avocados for sea export. S. A. Avocado Growers' Assn. Yrbk. 6:24-27.

Vorster, L.L., J.C. Toerien, and J.J. Bezuidenhout. 1987. A storage temperature regime for South African export avocados. S. A. Avocado Growers' Assn. Yrbk. 10:146-149.

Vorster, L.L. J.C. Toerien, and J.J. Bezuidenhout. 1990. Temperature management of avocados - an integrated approach. S. A. Avocado Growers' Assn. Yrbk. 13:43-46.

Fig. 1.

The incidence of cold damage on Westfalia

fruit in different vessels in 1988, 1989, and 1990.

Fig. 2.

The softness of Westfalia fruit on

arrival at Rungis in different vessels in 1988, 1989,

and 1990.

Fig. 3.

The influence of fruit age on the degree of softness on

arrival at Rungis.

Fig. 4.

Effects of temperature deviation with regard to fruit

firmness on young fruit at Westfalia for 1990.

Fig. 5.

Effects of temperature deviation with regard to fruit

firmness on old fruit at Westfalia for 1990.